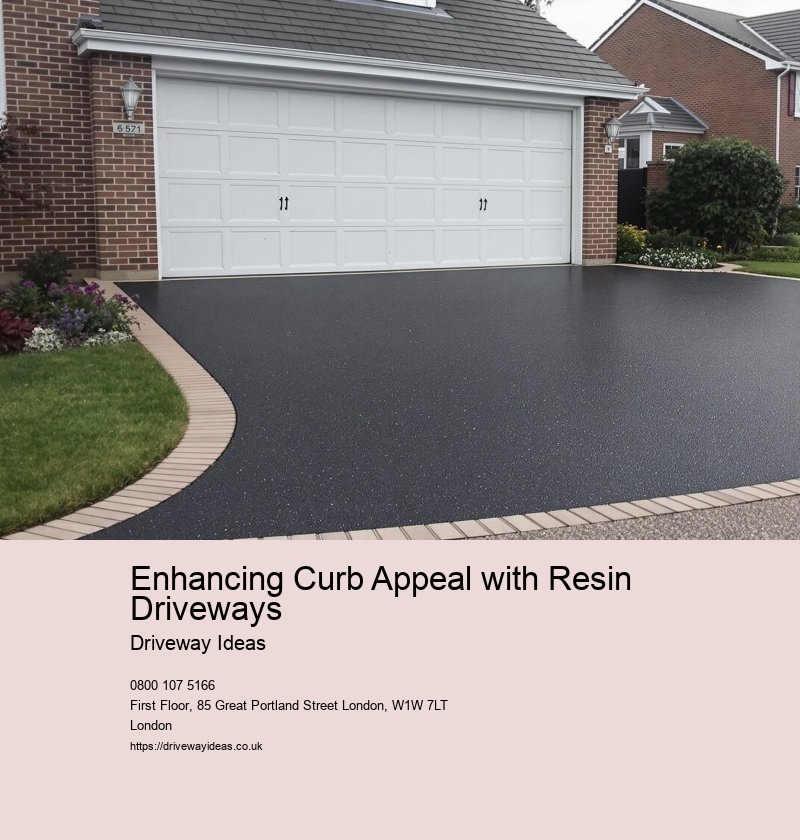

Enhancing Curb Appeal with Resin Driveways

Preparing the Base

When it involves mounting resin driveways, preparing the base is perhaps the most critical step (and one that you should not miss!). Budget-Friendly Resin Driveway Alternatives . You may believe it's almost laying some product down, yet it's alot more than that. Without a properly prepared base, your driveway won't stand the test of time, no matter how well you lay the resin.

To begin with, you have actually reached pick the right materials. An usual error people make is thinking any kind of old crushed rock will work. That's a big no-no! You require a sub-base that's secure and well-draining. Normally, a mix of smashed stone or accumulation (with a dimension of around 20mm) works finest. It's not nearly throwing it down, though. You need to compact it extensively. If it's not compacted, it wont supply the assistance your driveway needs, and you'll wind up with undesirable splits or, even worse, the whole thing may start to sink.

Once youve got your products sorted, it's time to dig. You angle simply dig a little and expect the very best. The depth of your excavation need to go to least 250mm, however it varies depending upon the type of soil and the meant use of the driveway. If heavy vehicles will certainly be utilizing it, you could need to go deeper to make certain stability. Oh, and do not forget drainage! Without proper drain, water can collect and damage the base, leading to early failing.

Next, theres the value of a geotextile membrane layer. It functions as an obstacle (stopping the mixing of the sub-base with the soil below) and aids with drain. A lot of individuals miss this action, believing its unnecessary, yet believe me, it deserves the initiative. It could not appear like a huge bargain currently, but over time, it'll conserve you from migraines and added expenses.

After you have actually compressed your sub-base, it's time to level it out. Resin bonded driveway alternatives offer various textures and finishes, providing options like a menu at a five-star restaurant. This is where interest to information truly matters. If your base isn't level, the resin will not lay equally, resulting in an unequal surface that's not just unappealing however additionally a tripping hazard. Make use of a level to make sure every little thing is even and readjust where essential.

To conclude, while preparing the base for a resin driveway might seem like a lot of job, it's a step you can not afford to disregard. Missing or rushing via it will only result in issues in the future. So

Mixing the Resin and Accumulation

Mixing the Resin and Accumulation: A Crucial Action In Putting Up Resin Driveways

When it involves installing a resin driveway, one step thats absolutely vital is blending the resin and aggregate. Its not something you can simply rush with or ignore, because the quality of this combination will inevitably figure out exactly how resilient and appealing your driveway will be. Oh, and allow me inform you, getting it right can make all the distinction!

To begin with, you need to ensure youve got the right devices and materials. Youll require a paddle mixer (those points are life-savers!) and a tidy mixing location. Its vital to keep whatever clean since also a bit of dirt can mess points up. You don't desire that, do you? Additionally, make certain to gauge the resin and aggregate appropriately. Don't just eyeball it-- precision is key.

When youre ready, start by pouring the material into a mixing container. Its crucial that the resin is mixed thoroughly before adding any accumulation. This guarantees that the resin will certainly layer each item of accumulation evenly, which is important for the toughness of the driveway. If the material isn't blended well, it wont bind effectively, and the driveway might begin to crumble in time. Yikes!

After the material is effectively mixed, you can begin to add the aggregate. Do this gradually and gradually-- including too much at once can bring about globs (and nobody wants clumps). Stir continuously to make sure everything is uniformly distributed. You may believe youre done once it looks well-mixed, but give it a couple of extra mixes simply in case. Its better to be risk-free than sorry, ideal?

Currently, heres something that people frequently neglect: do not mix too much at once! If you blend a large set and cant use it swiftly, it might begin to establish prior to you even lay it down. That would be a genuine frustration. So, mix in smaller sized batches that you can deal with within the working time.

Lastly, keep in mind that ambient problems (like temperature level and humidity) can impact exactly how the resin treatments. Its not something to be ignored. Make sure to take these aspects right into account before beginning the blending procedure.

In conclusion, mixing the material and aggregate may seem like a straightforward step, yet its one you angle afford to misunderstand. With a bit of care and interest, youll have the ability to create a magnificent and durable material driveway that not only boosts your buildings suppress allure yet additionally stands the examination of time!

Laying the Resin Surface Area

Laying the material surface area is one of one of the most essential steps in installing a material driveway. Oh, but don't allow that daunt you! It's not as daunting as it sounds, and with a little perseverance and attention to information, you can achieve a smooth, durable coating.

First points initially, you don't simply start pouring resin all over (that would be a mess). You require to prepare the surface area carefully. See to it its tidy, completely dry, and without any loose debris. If there's a fleck of dust, it might spoil the entire appearance. So, do not avoid this step unless you intend to remodel the entire thing. As soon as your base is ready, you can go on to blending the material.

Mixing the material appropriately is crucial. You will not want a blend thats as well thick or too dripping. It's got to be ideal. Normally, material can be found in two parts, the resin itself and a hardener. When these two parts are blended, they create a chemical reaction that offers the material its stamina. But be careful! If you blend them incorrectly, you could wind up with a surface that does not set at all. Follow the producer's guidelines to the t.

Currently, heres where the genuine enjoyable begins-- laying the resin. Using a trowel or a squeegee, spread out the combined resin equally over the driveway. You don't want any lumps or uneven areas, so take your time. Operate in workable sections, making certain each location is smooth before carrying on. It's no race; perseverance is your pal here. Be sure you're not laying it also thick, as this might bring about breaking later on.

Oh, and don't neglect to include the accumulation (those little stones)! Thoroughly spread them across the surface while the resin is still wet. This will give your driveway that attractive, textured appearance and supply additional grip. It's not just for visual appeals; it's for security, as well.

As soon as you have actually laid down the resin and aggregate, its time to let it treat. Do not hurry this process. You shouldn't stroll or drive on the surface up until it's completely established. The curing time can vary depending upon the climate, so watch on the forecast. Rainfall is not your pal at this stage.

To conclude, laying the resin surface area needs cautious prep work, accurate blending, and patient application. Its not something you can hurry via, however with these actions, you're well on your means to having a magnificent material driveway

Finishing Touches and Healing Refine

Setting up a resin driveway is a rewarding task that can change the aesthetic allure of your home. Nevertheless, its vital to take note of the finishing touches and curing procedure to make sure the driveways durability and look. Lots of people often neglect these final steps, but theyre essential for a remarkable finish.

As soon as the material mix is applied and smoothed out, the actual magic begins with the completing touches. This includes meticulously checking the surface for any type of blemishes. Little air bubbles or unequal places? Don't panic! They can be gently smoothed over with a trowel or roller. Its crucial not to hurry this process; besides, persistence is vital. Youll want to ensure that the surface is also and constant.

But wait-- theres even more to it than just smoothing. The boundaries of the driveway should be neat and tidy, which could require trimming any type of excess product. This is where interest to detail actually shines. Ensure the sides are tidy and straight, as it produces a specialist look that will certainly wow anybody that sees it.

Currently, lets talk about the curing process. This is the phase where lots of people (surprisingly) make errors. The material requires time to establish effectively to achieve maximum strength and durability. Its tempting to use the driveway quickly, but hold your equines! Its suggested to avoid any type of foot traffic for a minimum of 1 day and car website traffic for as much as 2 days. This ensures that the surface area solidifies completely and can withstand the deterioration of everyday usage.

Throughout this duration, its vital to keep the driveway devoid of particles, leaves, or anything that might leave marks. An easy cover or barrier can be helpful to maintain undesirable aspects away. This might appear like an unneeded step, yet its vital to not skip it. The healing process is not nearly drying out; its regarding allowing the resin bond totally with the accumulation to create a resistant surface area.

In conclusion, while the setup of a resin driveway is a substantial task, the finishing touches and healing process are what establish its success. Do not be lured to avoid these steps or thrill via them. brick paving driveway options Ensuring the surface area is ideal and permitting sufficient time for healing will cause a lovely, sturdy driveway that will stand the test of time. Remember, its those last information that make all the difference!

Preparing the Base

When it involves mounting resin driveways, preparing the base is perhaps the most critical step (and one that you should not miss!). Budget-Friendly Resin Driveway Alternatives . You may believe it's almost laying some product down, yet it's alot more than that. Without a properly prepared base, your driveway won't stand the test of time, no matter how well you lay the resin.

To begin with, you have actually reached pick the right materials. An usual error people make is thinking any kind of old crushed rock will work. That's a big no-no! You require a sub-base that's secure and well-draining. Normally, a mix of smashed stone or accumulation (with a dimension of around 20mm) works finest. It's not nearly throwing it down, though. You need to compact it extensively. If it's not compacted, it wont supply the assistance your driveway needs, and you'll wind up with undesirable splits or, even worse, the whole thing may start to sink.

Once youve got your products sorted, it's time to dig. You angle simply dig a little and expect the very best. The depth of your excavation need to go to least 250mm, however it varies depending upon the type of soil and the meant use of the driveway. If heavy vehicles will certainly be utilizing it, you could need to go deeper to make certain stability. Oh, and do not forget drainage! Without proper drain, water can collect and damage the base, leading to early failing.

Next, theres the value of a geotextile membrane layer. It functions as an obstacle (stopping the mixing of the sub-base with the soil below) and aids with drain. A lot of individuals miss this action, believing its unnecessary, yet believe me, it deserves the initiative. It could not appear like a huge bargain currently, but over time, it'll conserve you from migraines and added expenses.

After you have actually compressed your sub-base, it's time to level it out. Resin bonded driveway alternatives offer various textures and finishes, providing options like a menu at a five-star restaurant. This is where interest to information truly matters. If your base isn't level, the resin will not lay equally, resulting in an unequal surface that's not just unappealing however additionally a tripping hazard. Make use of a level to make sure every little thing is even and readjust where essential.

To conclude, while preparing the base for a resin driveway might seem like a lot of job, it's a step you can not afford to disregard. Missing or rushing via it will only result in issues in the future. So

Mixing the Resin and Accumulation

Mixing the Resin and Accumulation: A Crucial Action In Putting Up Resin Driveways

When it involves installing a resin driveway, one step thats absolutely vital is blending the resin and aggregate. Its not something you can simply rush with or ignore, because the quality of this combination will inevitably figure out exactly how resilient and appealing your driveway will be. Oh, and allow me inform you, getting it right can make all the distinction!

To begin with, you need to ensure youve got the right devices and materials. Youll require a paddle mixer (those points are life-savers!) and a tidy mixing location. Its vital to keep whatever clean since also a bit of dirt can mess points up. You don't desire that, do you? Additionally, make certain to gauge the resin and aggregate appropriately. Don't just eyeball it-- precision is key.

When youre ready, start by pouring the material into a mixing container. Its crucial that the resin is mixed thoroughly before adding any accumulation. This guarantees that the resin will certainly layer each item of accumulation evenly, which is important for the toughness of the driveway. If the material isn't blended well, it wont bind effectively, and the driveway might begin to crumble in time. Yikes!

After the material is effectively mixed, you can begin to add the aggregate. Do this gradually and gradually-- including too much at once can bring about globs (and nobody wants clumps). Stir continuously to make sure everything is uniformly distributed. You may believe youre done once it looks well-mixed, but give it a couple of extra mixes simply in case. Its better to be risk-free than sorry, ideal?

Currently, heres something that people frequently neglect: do not mix too much at once! If you blend a large set and cant use it swiftly, it might begin to establish prior to you even lay it down. That would be a genuine frustration. So, mix in smaller sized batches that you can deal with within the working time.

Lastly, keep in mind that ambient problems (like temperature level and humidity) can impact exactly how the resin treatments. Its not something to be ignored. Make sure to take these aspects right into account before beginning the blending procedure.

In conclusion, mixing the material and aggregate may seem like a straightforward step, yet its one you angle afford to misunderstand. With a bit of care and interest, youll have the ability to create a magnificent and durable material driveway that not only boosts your buildings suppress allure yet additionally stands the examination of time!

Laying the Resin Surface Area

Laying the material surface area is one of one of the most essential steps in installing a material driveway. Oh, but don't allow that daunt you! It's not as daunting as it sounds, and with a little perseverance and attention to information, you can achieve a smooth, durable coating.

First points initially, you don't simply start pouring resin all over (that would be a mess). You require to prepare the surface area carefully. See to it its tidy, completely dry, and without any loose debris. If there's a fleck of dust, it might spoil the entire appearance. So, do not avoid this step unless you intend to remodel the entire thing. As soon as your base is ready, you can go on to blending the material.

Mixing the material appropriately is crucial. You will not want a blend thats as well thick or too dripping. It's got to be ideal. Normally, material can be found in two parts, the resin itself and a hardener. When these two parts are blended, they create a chemical reaction that offers the material its stamina. But be careful! If you blend them incorrectly, you could wind up with a surface that does not set at all. Follow the producer's guidelines to the t.

Currently, heres where the genuine enjoyable begins-- laying the resin. Using a trowel or a squeegee, spread out the combined resin equally over the driveway. You don't want any lumps or uneven areas, so take your time. Operate in workable sections, making certain each location is smooth before carrying on. It's no race; perseverance is your pal here. Be sure you're not laying it also thick, as this might bring about breaking later on.

Oh, and don't neglect to include the accumulation (those little stones)! Thoroughly spread them across the surface while the resin is still wet. This will give your driveway that attractive, textured appearance and supply additional grip. It's not just for visual appeals; it's for security, as well.

As soon as you have actually laid down the resin and aggregate, its time to let it treat. Do not hurry this process. You shouldn't stroll or drive on the surface up until it's completely established. The curing time can vary depending upon the climate, so watch on the forecast. Rainfall is not your pal at this stage.

To conclude, laying the resin surface area needs cautious prep work, accurate blending, and patient application. Its not something you can hurry via, however with these actions, you're well on your means to having a magnificent material driveway

Finishing Touches and Healing Refine

Setting up a resin driveway is a rewarding task that can change the aesthetic allure of your home. Nevertheless, its vital to take note of the finishing touches and curing procedure to make sure the driveways durability and look. Lots of people often neglect these final steps, but theyre essential for a remarkable finish.

As soon as the material mix is applied and smoothed out, the actual magic begins with the completing touches. This includes meticulously checking the surface for any type of blemishes. Little air bubbles or unequal places? Don't panic! They can be gently smoothed over with a trowel or roller. Its crucial not to hurry this process; besides, persistence is vital. Youll want to ensure that the surface is also and constant.

But wait-- theres even more to it than just smoothing. The boundaries of the driveway should be neat and tidy, which could require trimming any type of excess product. This is where interest to detail actually shines. Ensure the sides are tidy and straight, as it produces a specialist look that will certainly wow anybody that sees it.

Currently, lets talk about the curing process. This is the phase where lots of people (surprisingly) make errors. The material requires time to establish effectively to achieve maximum strength and durability. Its tempting to use the driveway quickly, but hold your equines! Its suggested to avoid any type of foot traffic for a minimum of 1 day and car website traffic for as much as 2 days. This ensures that the surface area solidifies completely and can withstand the deterioration of everyday usage.

Throughout this duration, its vital to keep the driveway devoid of particles, leaves, or anything that might leave marks. An easy cover or barrier can be helpful to maintain undesirable aspects away. This might appear like an unneeded step, yet its vital to not skip it. The healing process is not nearly drying out; its regarding allowing the resin bond totally with the accumulation to create a resistant surface area.

In conclusion, while the setup of a resin driveway is a substantial task, the finishing touches and healing process are what establish its success. Do not be lured to avoid these steps or thrill via them. brick paving driveway options Ensuring the surface area is ideal and permitting sufficient time for healing will cause a lovely, sturdy driveway that will stand the test of time. Remember, its those last information that make all the difference!